British company Helix has introduced a new aircraft concept that could reduce fuel consumption by up to 90% on short-haul routes. The innovation centers around a hybrid-electric propulsion system, combining lightweight high-density motors with ducted fans to significantly cut fuel use.

Helix, known for its work in electric motor development, detailed the project in its recent white paper titled “A New Architecture for Aviation.” The document outlines a three-phase approach to modernizing regional and private aircraft using currently available technologies.

Запропонована система поєднує гібридну електричну схему, легкі двигуни високої щільності та вентиляторну тягу, що дає змогу скоротити витрати палива до 23,8 кг кілограмів на рейс.

Designed for flights up to 465 kilometers – which account for roughly a quarter of all global air traffic – this new architecture offers a practical route toward reducing emissions and improving efficiency.

Fuel accounts for nearly 30% of an airline’s operational costs, and that percentage is often even higher for short-haul operators. As regulations continue to push the aviation industry toward sustainable aviation fuel (SAF) – which is expected to remain more expensive than conventional fuel in the long term – these fuel-related costs are likely to rise significantly in the coming years.

Flights covering distances of up to 500 kilometers account for more than 26% of global air traffic and represent a fast-growing market segment, projected to reach $115 billion by 2035. However, these routes often come with high fixed costs and significant fuel consumption per kilometer.

According to Helix, while electrification offers a promising path toward emissions reduction, fully electric aircraft remain limited by the current energy density of batteries. For example, an electric aircraft weighing 8,500 kilograms and powered by commercially available batteries with an energy density of 205 watt-hours per kilogram would only be capable of flying approximately 263 kilometers – well short of typical regional route requirements.

The company proposes a more practical solution: serial hybridization. By replacing part of the battery pack with a compact generator and liquid fuel, the aircraft can achieve a flight range of up to 465 kilometers while using just 59.5 kilograms of fuel – representing a 74.3% reduction compared to conventional aircraft. This design allows the aircraft to operate purely on electric power during critical phases such as takeoff and landing, while recharging its fuel cells during cruise.

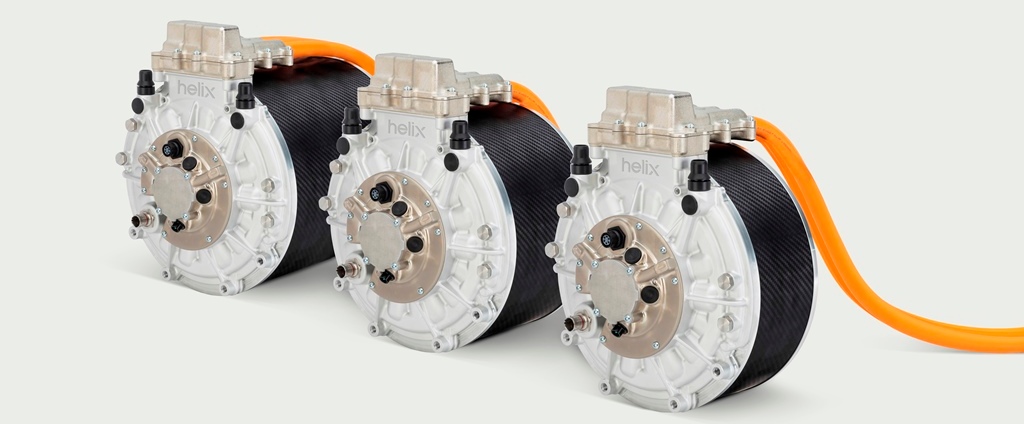

According to Helix, this approach marks a significant step forward for low-emission, cost-effective aviation on short routes using existing technology. A key factor in further reducing fuel consumption is lowering the weight of the propulsion system. Replacing the baseline MagniX650 engine – which weighs around 205 kilograms per unit – with the lighter Helix SPX417-200 engine contributes notably to this efficiency gain.

The Helix engine delivers 568 kW of continuous power while weighing only 90 kg. When paired with a lighter inverter, the complete electric propulsion unit weighs just 124 kg – enabling a total weight savings of 162 kg across both engines. This weight reduction allows the aircraft to carry an additional 36.7 kWh of battery energy, lowering fuel consumption by 11.1%, from 59.5 kg to 52.9 kg.

Further efficiency gains come from using a motor-gearbox configuration, which reduces the EPU’s mass by an additional 222 kg. This change enables an increase in battery energy capacity by 45.5 kWh and brings fuel usage down to 50.2 kg – a total reduction of 15.7%. As a result, the aircraft consumes just 21.7% of the fuel required by a conventional aircraft.

Such optimization of the powertrain – achieved through advanced lightweight motors and transmission systems – greatly enhances flight efficiency while preserving the key advantages of a hybrid-electric architecture.

The final improvement in fuel efficiency is achieved by transitioning to a ducted fan propulsion system. Unlike open propellers, ducted fans enclose the blades within a cylindrical housing, which reduces tip losses and significantly improves static thrust efficiency. This design enables the generation of the same level of thrust while consuming 25% less shaft power.

Although this configuration adds 91.2 kg of weight due to the nacelle structure and increases aerodynamic drag – slightly reducing the optimal cruise speed from 81 m/s to 77 m/s – the overall propulsion efficiency increases substantially.

The combination of a high energy-density motor and a geared transmission enables an additional 33.2 kWh of energy to be drawn from the battery, significantly reducing the amount of fuel required for flight. This configuration not only improves energy conversion efficiency but also lowers noise levels and reduces the risk of blade damage – critical considerations for regional airports that are sensitive to noise pollution.

Helix reports a 60% reduction in fuel consumption compared to a baseline hybrid system, and just 10.3% of the fuel use of a conventional aircraft over a 465-kilometre route. This marks a major breakthrough in the development of environmentally sustainable aviation.

Source: interestingengineering